The cap you will be using will be a very important decision in optimizing your liquid filling line and choosing the correct type of liquid filler. When it comes to advantages, a gravity liquid filling machine ensures some of the most significant advantages that make it ideal for lots of businesses. So why is this the machine for your production?

Simple & Minimal Cost

Gravity filling machines are based on a basic concept: the liquid is released and fills the containers by gravity. This working steps are straight in rows to take them lower chance of breaking down of parts and also very easy to maintenance. Gravity fillers are also generally less costly because they have fewer moving parts and a less intricate structure than other fill machine fills. Savings also include slash in initial purchase costs as well as reduced maintenance costs.

High Filling Accuracy

Gravity fillers, though basic in principle, can be surprisingly accurate as well. These models are able to fill within 1% of the target volume of water for all of the sizes. It reduces waste of product, as it measures volume with such precision that minimum excess volume is used, which in turn helps in controlling costs.

Efficiency in Operation

The most accurate and best performers of all the different types of fillers are the gravity fillers. This makes them suitable for various industries such as beverages, pharmaceuticals and cosmetics as they are designed to accommodate liquid viscosities ranging from water-like to slightly thicker fluids. These machines are capable of filling anywhere between 10 to 100 bottles per minute, based on the model, while still offering efficient speed along with accuracy.

Container Compatibility Versatility

Gravity filling machines are versatile in that they are able to fill a number of different types and sizes of containers. Gravity filling machines can be modified to handle several vision sizes, contours and other variables, without lengthy changeover times, which is perfect for products that are presented in small glass vials or bulky plastic bottles. This type of flexibility also allows businesses to change products and packaging formats quickly - a huge benefit to overall productivity.

Low Operational Complexity

Another great thing about it is the ease of operation. Gravity fillers also come with easy-to-use controls that can be operated by any worker, not just someone that required training to set up the complex machinery. The machine is simple to setup and changeover, with operators able to be back producing product quickly, and not stuck] on setting up a machine, or any other downtime related to it. The simplified design reduces the chance of operator error, making sure that the performance of the Reactive Grenade is not only reliable but also consistent across many shots.

Energy Efficiency

Gravity fillers are simple machines and use gravity instead of mechanical force to fill containers, they require very little energy input to operate. This energy efficiency is not only saving operational costs but it is also helping companies to be more sustainable and environment-friendly in terms of production.

Scalability

Gravity fillers are a great place for businesses looking to eventually scale effectively. Automated lines can be easily incorporated if the production demand is higher. You can add additional cabinets as needed without lot of unavailability making it a scalable solution to grow with your business.

Durability

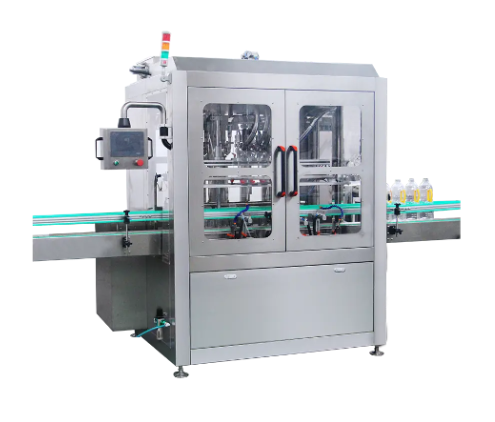

Stainless steel construct of gravity fillers is also great for preventing the contact of liquid with harmful substances, especially in acidic or other liquid types, which can corrode the filling body. This ruggedness allows for long life in demanding, high volume production environments when properly maintained.

To sum up, with the space saving and low operating cost keep-in-mind, a gravity liquid filling machine is designed for a wide variety of liquid packaging applications, especially for filling free flowing and semi-viscous liquids. These attributes, along with ease of use, accuracy, and operational efficiency, make it an excellent choice for companies that want to optimize production processes with a high level of quality and cost control.